Description

Nidek Lite Oxygen VET Concentrator

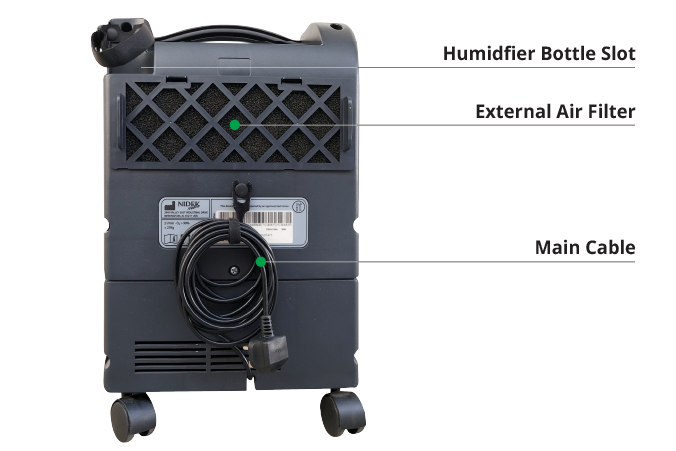

The Nidek Lite Oxygen VET Concentrator offers reliable oxygen delivery in a compact, lightweight design. It provides up to 5 LPM flow with ~90% purity, operates quietly, and features user-friendly controls. Ideal for home or clinical use, it combines portability, efficiency, and durability for continuous oxygen therapy.

- 5L Max outlet Rating

- Size: 360 x 220 x 580 mm

- Weight : 13.6 Kgs

- Continuous flow settings: 0.125 – 5 LPM, from Paediatric to Adult

- Oxygen concentration: 90% (+6.5% / -3%) at 5 LPM

- Oxygen output pressure: 7 PSI

- Sound level: Less Than 40 dBA

- Power specification: 230 V, 50 Hz

- Power consumption: 290 W

- Filters: cabinet, Compressor Intake and Bacteria

- Quiet – Ultra quiet operation, sound level <40 dBA

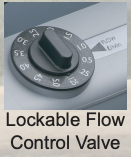

- Accurate – Lockable flow control valve, range from 0.125 – 5 LPM

- Economical – Very low power consumption, only 290 W

- Superior design – Direct access to air inlet filer, electronic hour meter and alarm battery

- Reaches full purity in less than 3 minutes

- High efficiency Thomas compressor

- Easy usage and maintenance

- Operating system – Timed cycle / Rapid Pressure Swing

- Self monitoring alarm system (in OMS model)

Nidek Lite Oxygen VET Concentrator Description of Operation

Air enters the Nidek Nuvo Family Oxygen Concentrator through an external cooling air intake filter. This filtered air enters the compressor via a suction resonator and fine filter, which quiets the suction sounds made by the compressor. Pressurized air then exits the compressor and passes through a heat exchanger, which reduces thetemperature of the compressed air. Next, an electronic valve system directs the air into one of two sieve beds that contain molecular sieve. The special characteristic property of molecular sieve is that it physically attracts (adsorbs) nitrogen when air passes through this material, thus enabling the production of high purity oxygen.

There are two sieve beds or adsorbent columns; while one produces high purity oxygen, the other is purged of the nitrogen it adsorbed (collected) while it wasproducing oxygen. Each column produces oxygen for approximately 5.5 seconds and delivers it to the product storage volume in the end of the column. Oxygen exits the adsorbent column through a pressure regulator, flow control valve, flow meter, and final product filter. The flow control valve, which is part of the flow meter, controls the flow rate of oxygen delivered to the patient. The Nuvo Family unit delivers up to 95% oxygen concentration at rated flow. The remaining constituents of the product gas stream are nitrogen and argon, both of which are part of the air we breathe, are inert and are completely safe. Its a superb little oxygen machine

Additional information

| Weight | 15 kg |

|---|